Automotive & other Industrial

Automotive & other Industrial

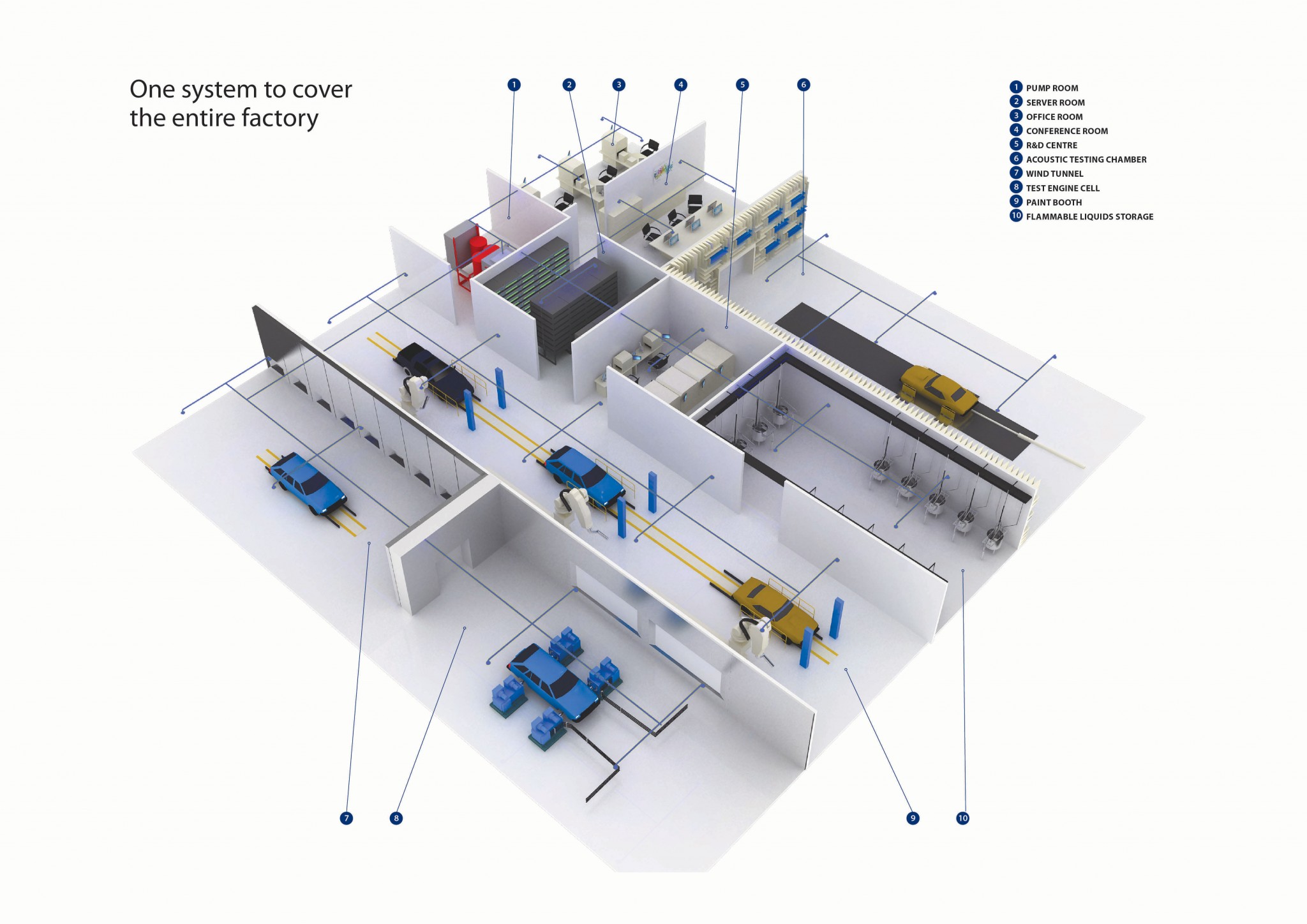

With SEM-SAFE® high-pressure water mist technology all areas in a car factory can be protected

Click on the image above to enlarge

Reliable and safe fire fighting system for any car factory

Tested according to VdS protocol, the SEM-SAFE® high-pressure water mist system is the optimum fire fighting solution for any application in a car factory, such as paint booths, wind tunnels, engine test cells, research and development rooms, environmental testing chambers, flammable liquids storage, acoustic testing chambers, server rooms, etc.

In comparison to traditional fire fighting systems, such as gas based systems, the SEM-SAFE® high-pressure water mist system does not require evacuation as it is completely harmless to people. This means rapid activation upon fire detection. Also the SEM-SAFE® system is ready to be re-used immediately, if needed, while gas systems require time consuming refilling and rechecking.

Another significant advantage of SEM-SAFE® is that it has superior cooling properties. The radial heat is blocked, offering protection against any structural damage as flames cannot expand.

In comparison with traditional sprinkler system, the SEM-SAFE® high-pressure water mist system uses very little water. This means that the system is overall lighter and that in case of a fire, the water damage is kept to a minimum. This is imperative for ensuring continuity of the production lines in a car factory.

Limited downtime with SEM-SAFE® by Danfoss

KGHM copper mine and mill, Poland: Protected with SEM-SAFE® by Danfoss

SEM-SAFE® high-pressure water mist for fire protection is extremely suitable for areas where disruption of the manufacturing process has to be reduced to a minimum in case of a fire and where there is a lot of sensitive equipment.

SEM-SAFE® high-pressure water mist offers ideal fire protection for various industrial applications such as:

- Generators

- Engines

- Power plants

|

- Industrial production lines

- Cable tunnels

- Food processing industry

|

Improved safety and reliability

- The SEM-SAFE® system protects all machinery where the fire hazard actually occurs, catching and extinguishing the fire quickly

- The system has been documented to be harmless to electrical equipment with at least IP 22

- It prevents shock cooling of cast parts

- Water mist cools cables and metal so that no heat damage occurs

- Faster activation than gas based systems

- Minimum water damage, due to lowest possible water consumption

Minimum water damage in case of a fire

- A water mist system uses 90% less water than a drencher system and most of it evaporates, leaving minimal amounts of water after a fire

- All piping is stainless steel; thus the dispersed water is clean compared to polluted water dispersed from sprinkler system

Crefeld Cargill, Diesel Engine, Germany: Protected with SEM-SAFE® by Danfoss

To learn more about the benefits of the SEM-SAFE® high-pressure water mist system please click here.