SEM-SAFE® by Danfoss High-Pressure Water Mist Fire Fighting System

SEM-SAFE® by Danfoss High-Pressure Water Mist Fire Fighting System

The intelligent use of water

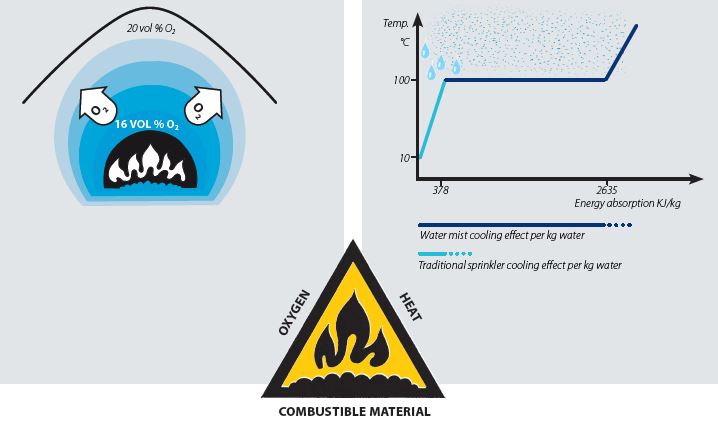

For centuries, water has been used as a medium to fight fires by cooling the fire. The breakthrough that water mist represents is to use the same method as traditional sprinklers but to add the effect of converting the water into steam. This means that the cooling effect is up to seven times higher.

If we look at the fire triangle, a fire relies on the presence of three elements in order to survive; oxygen, heat and combustible material. The removal of any one of these elements will extinguish a fire.

A high-pressure water mist system goes further: it attacks two elements of the fire triangle: oxygen and heat. This means that water mist combines the suppression effect of gas and traditional sprinkler systems. As well as removing the oxygen like gas system, it simultaneously cools the fire like a traditional sprinkler.

For more detailed information about the oxygen and heat displacement, click here.

The power behind SEM-SAFE®

The SEM-SAFE® water mist system is a unique fire fighting system. By forcing water at a high pressure through nozzles, an extremely fine mist is created.

Water is supplied via a pump unit. The SEM-SAFE® pump unit can supply all water mist applications. This is beneficial because you only need one unit for all applications, and it is easy to add more sections and applications, if needed. In addition, servicing of only one unit is easier and less costly.

1. SEM-SAFE® water mist system with closed nozzles

On stand-by, the system maintains a pipe pressure of approx. 12 bar. When the temperature exceeds e.g. 57 °C, the heat-sensitive glass bulbs mounted in the nozzle heads melt. At this point, the high-pressure pump is automatically activated and water is forced through nozzles at high-pressure (60 or 100 bar depending on nozzle type) to create a fine mist. Only nozzles with melted bulbs are activated. This means that only the heat-affected area will be actively sprayed.

2. SEM-SAFE® water mist system with open nozzles

On stand-by, the system has dry piping. This system will activate manually or when sensors have detected heat, smoke or a flame, depending on type and application. The nozzles are grouped in sections and all the nozzles in the activated section will be released.

3. SEM-SAFE® water mist system in operation

During operation, the high-pressure pump draws water from the tank on unit (a non-pressurised stainless-steel tank) and forces it through a non-return valve to a high-pressure manifold. From here, it is distributed to the relevant section(s) via the section valve. A pressure relief valve controls the pump pressure and is designed to return the full pump capacity to the tank on unit.

Schematic diagram and main components for SEM-SAFE® high-pressure water mist system

The benefits of SEM-SAFE® high-pressure water mist system

Quick fire fighting

- As water mist both cools the fire and removes the oxygen, it results in quicker fire fighting

- Due to the cooling effect of water mist, re-ignition is avoided

- The SEM-SAFE® water mist system is ready for re-use immediately after a fire

Less damage

- Water damage is kept at a minimum due to the low water consumption of the high pressure water mist system

- The SEM-SAFE® system can be deployed instantly, resulting in less damage

- Using only pure water, the SEM-SAFE® water mist system gives you the best possible protection of equipment and human lives

Reduced down time

- The reduced amount of damage often means less down time, resulting in much lower costs

- There is no need to fill up cylinders, thus saving expensive refilling time and overall costs

No need for extra installations

- The pump unit takes up little space and needs no special room or safe storage

- Easy and fast installation is possible due to small pipe sizes and low system weight

Read our brochure about SEM-SAFE® high-pressure water mist here.